How are lithium-ion batteries manufactured

The manufacturing process of lithium-ion batteries can be divided into three main stages: pre process, mid process, and post process.

Pre process

The main goal of the front-end process is to complete the production of positive and negative electrode plates. The specific steps include:

Pulping: Mix active substances, conductive agents, binders, and solvents evenly to form a stable slurry. This step has strict requirements for the formulation, dispersion uniformity, viscosity, etc. of the slurry, which directly affects the performance of the battery.

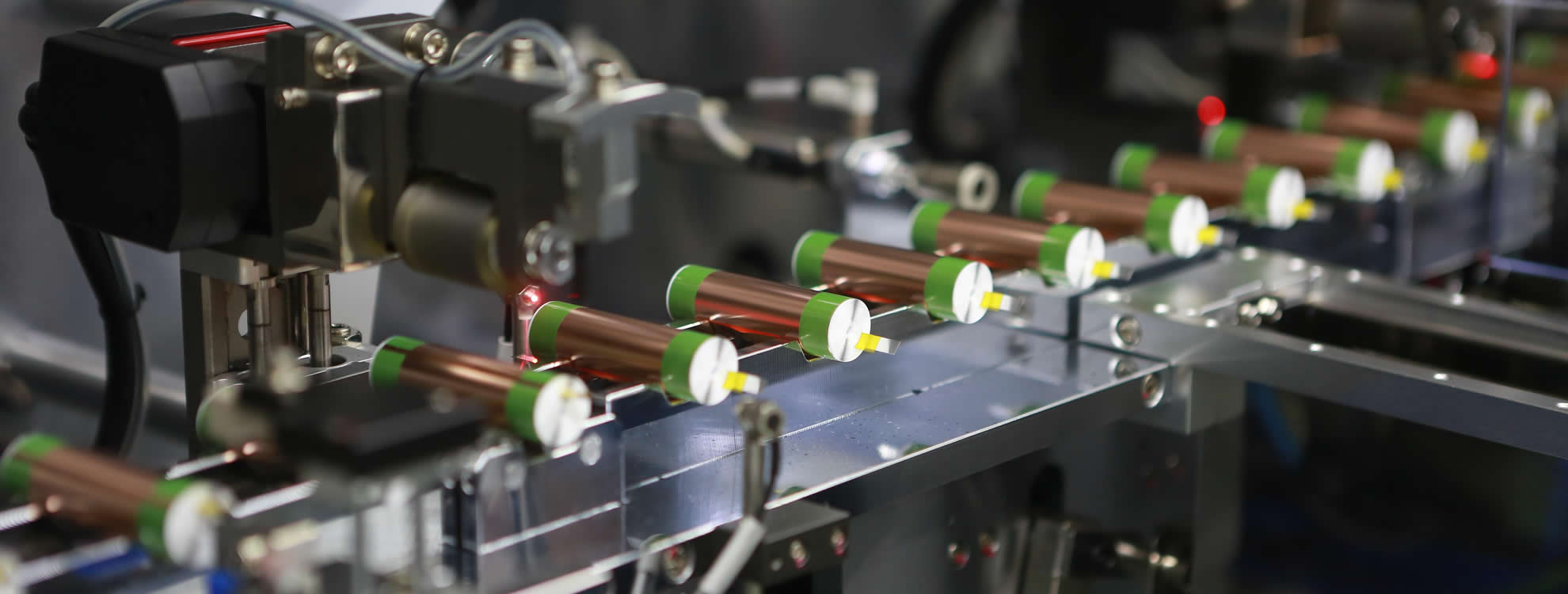

Coating: Coating the slurry onto a current collector (usually copper or aluminum), and then removing the solvent through drying to form a dry electrode sheet.

Roll pressing: The pole piece is compacted by a rolling machine to make its structure more compact.

Cutting: Cutting the polarizer into the desired size and shape.

Production and die-cutting: further processing the polarizer into the final polarizer shape.

Intermediate process

The goal of the intermediate process is to complete the manufacturing of the battery cells. The specific process of the intermediate stage varies depending on the type of battery (square, cylindrical, or soft pack):

Square and cylindrical batteries: including winding or assembly, liquid injection, packaging, and other steps. Use a winding machine or assembly equipment to assemble the polarizer with the separator and electrolyte into a battery cell, then inject the electrolyte and package it.

Soft pack battery: including steps such as lamination, injection, and packaging. Use a laminating machine to laminate the pole pieces into battery cells, then inject electrolyte and package them.

Subsequent process

The goal of the subsequent process is to complete the formation and packaging of the battery. The specific steps include:

Chemical conversion: Activate the battery through charging and discharging cycles.

Capacity division: Classify the capacity of batteries to ensure consistent performance of each battery.

Testing and Sorting: Conduct performance testing on batteries through testing equipment, and classify and screen them to ensure the quality of the final product.