The packaging of lithium-ion batteries mainly includes the following forms:

The packaging of lithium-ion batteries is mainly divided into three forms: cylindrical, soft pack, and square.

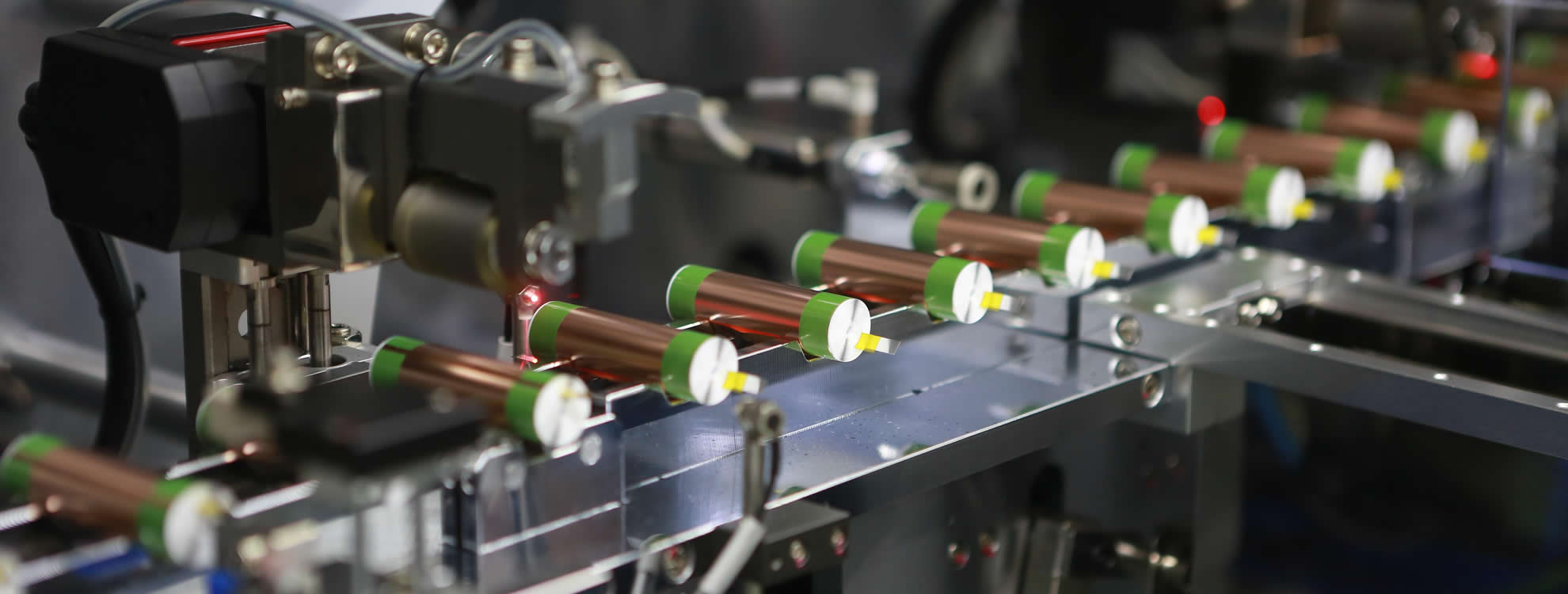

Cylindrical:

The shell is generally made of nickel plated steel plate or aluminum shell.

The production process is mature, the production efficiency is high, the cost is relatively low, the yield is higher than that of square lithium batteries and soft pack lithium batteries, and the consistency and safety are also excellent.

Soft package:

Using aluminum-plastic composite film for packaging, it has extremely high flexibility and can be molded into any shape.

Good safety performance and less prone to explosion; High energy density and light weight.

At present, it is necessary to address issues such as high standardization and cost, heavy reliance on imported aluminum-plastic films, and poor consistency.

Square:

The shell is mostly made of aluminum alloy, stainless steel and other materials, and the interior adopts winding or laminated technology.

The protective effect on battery cells is better than that of soft pack batteries, and the safety of battery cells has also been greatly improved compared to cylindrical batteries.

The structure is relatively simple, the overall accessory weight is light, and the relative energy density is high.

In addition, when packaging lithium-ion batteries, a series of safety and compliance requirements must be followed, such as clearly labeling the type and UN number of the lithium-ion battery, posting a hazardous goods label exclusive to the lithium-ion battery, etc., to ensure the safety of the lithium-ion battery during transportation.

In summary, there are various packaging forms for lithium-ion batteries, each with its unique advantages and applicable scenarios. When choosing, one should weigh the specific needs. At the same time, it is necessary to strictly comply with relevant safety and compliance requirements to ensure the safe use of lithium batteries.