The production of rechargeable battery packs can be carried out through the following steps:

Select battery type: Firstly, you need to determine the type and specifications of the battery pack to be produced. For example, you can choose 18650 lithium-ion batteries to make a high-capacity battery pack. This type of battery is commonly used in fields such as electric vehicles and mobile power sources, with high energy density and long cycle life.

Prepare materials and tools: Next, prepare the required batteries, battery management system (BMS), wires, connectors, insulation materials, and necessary tools such as screwdrivers, soldering stations, etc. BMS is an important component of the battery pack, which can monitor the status of the battery and ensure that it operates within a safe range.

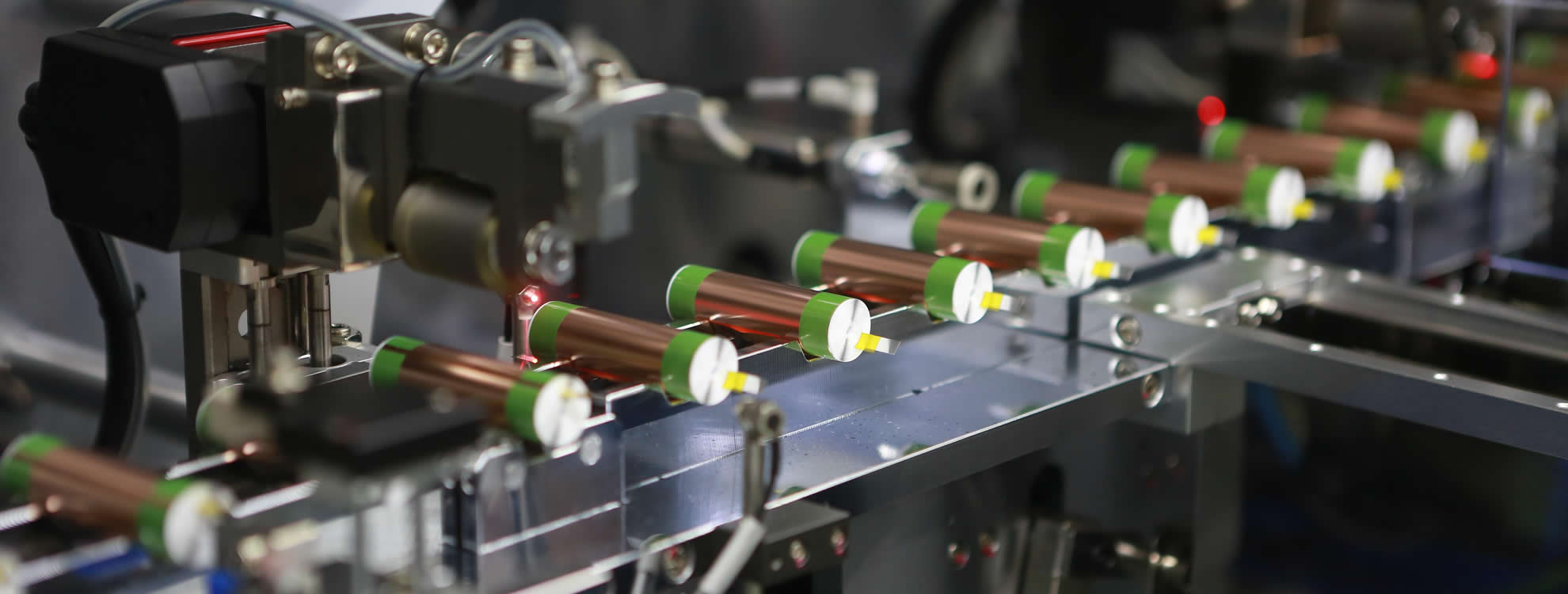

Assemble batteries: According to the designed battery pack structure, connect the batteries in series or parallel with positive and negative electrodes. During the connection process, it is important to ensure that the connection between the batteries is firm and well insulated to avoid short circuits or electric shock hazards. At the same time, attention should be paid to the arrangement and fixation of the batteries to ensure that the battery pack will not loosen or be damaged under vibration or impact.

Install BMS: Connect the BMS to the battery pack, ensuring that each battery is connected to the corresponding channel of the BMS. BMS can monitor parameters such as voltage, current, and temperature of the battery, and take protective measures when necessary, such as power-off or balanced charging, to ensure the safety and performance of the battery pack.

Testing and Debugging: After assembly, test and debug the battery pack. Use a multimeter and other tools to check the voltage, internal resistance, capacity, and other parameters of the battery pack to ensure that it meets the design requirements. At the same time, conduct charge and discharge tests to observe the working status and performance of the battery pack.

Packaging and Protection: Finally, the battery pack is packaged in a suitable casing to protect the battery from external environmental influences. The casing should have good heat dissipation performance and waterproof and dustproof functions to ensure that the battery pack can work stably even in harsh environments. At the same time, label the specifications, model, and precautions of the battery pack on the casing for ease of use and maintenance.

By following the above steps, you can create a rechargeable battery pack. However, safety must be taken into account during the production process, following relevant operating procedures and precautions to ensure personal and property safety. If you have any questions or uncertainties about the production or use of battery packs, it is recommended to consult professionals or relevant organizations for help and guidance.