Customized shape of lithium polymer battery

Lithium polymer batteries can be customized in shape. Lithium polymer batteries have ultra-thin characteristics and can be made into batteries of different shapes and capacities to meet the needs of products. The theoretical minimum thickness can reach 0.5mm. This means that lithium polymer batteries can be customized according to specific application requirements to accommodate various shapes and sizes.

Common shapes of lithium polymer batteries

1. Square: Square lithium polymer batteries are typically used for devices that require stable shape and large capacity, such as Bluetooth speakers, mice, etc.

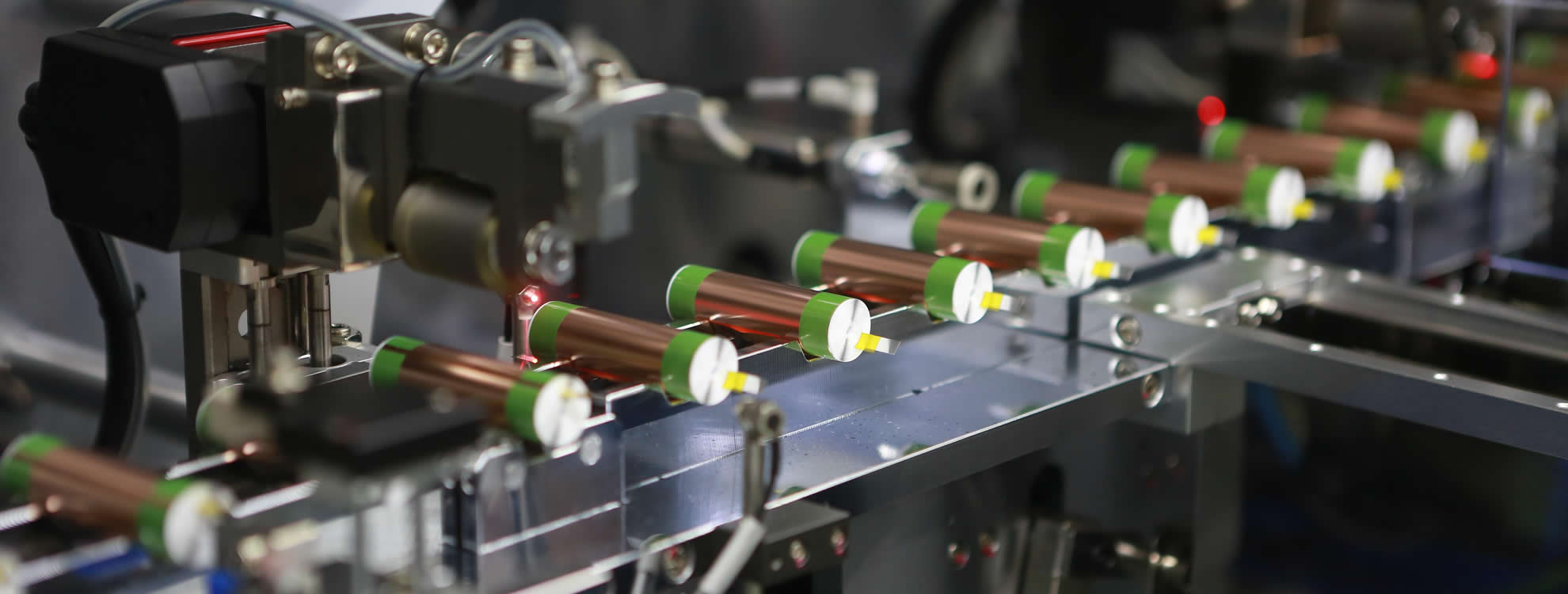

2. Cylindrical: Cylindrical lithium polymer batteries are commonly used in small electronic devices such as Bluetooth earphones, power tools, etc. Common sizes include 18650, 21700, etc.

3. Soft pack: Soft pack lithium polymer batteries have higher flexibility and can adapt to various complex shaped devices.

Customization process and cost considerations

1. Requirement analysis: Firstly, it is necessary to clarify the usage scenarios, capacity requirements, and shape requirements of the equipment.

2. Design and development: Design the shape and size of the battery according to the requirements, and conduct simulation testing to ensure performance and safety.

3. Production and testing: Strict quality control is required during the production process to ensure the performance and safety of the battery. Testing includes capacity testing, cycle life testing, etc.

4. Cost considerations: The cost of customizing batteries is usually higher as it requires additional design and production processes. However, for applications that require special shapes or high-capacity batteries, customized batteries may be a necessary choice.